Challenges and Solutions in Building Large Aquariums

Building a large aquarium requires expertise, precision, and a clear focus on both technical and biological requirements. From the initial design to the final installation and maintenance, every step is crucial to ensure the tank’s integrity and the safety of its inhabitants. Based on my experience, here are the most common challenges and the essential solutions that contribute to the success of these impressive aquatic installations.

Table of Contents

Key Considerations in Large Aquarium Design

Cost vs. Installation Method of Tank and Panels

In my experience, success in large aquarium construction begins with thoughtful tank design and acrylic panel planning. A clear understanding of production costs relative to the installation methods ensures efficiency and budget control from the start. Selecting the right acrylic manufacturer and matching it to the installation technique is essential for creating a flawless, long-lasting aquarium.

Expert Installation for Acrylic Panels

A significant risk in large aquariums is improper panel installation, leading to leaks or structural issues. Having worked on multiple large-scale aquariums, I can attest that the best results come from selecting installation experts with experience in high-pressure environments. For example, ICM’s experience with Aviapark Aquarium in Moscow showcases the complexity involved in managing installations for record-breaking cylindrical aquariums.

Concrete Design and Waterproofing for Marine Tanks

Specialized Waterproof Concrete for Saline and Biological Environments

Using the correct concrete design and admixture specifications is critical in saltwater aquariums. Saltwater and biological waste create a challenging environment for typical concrete, which can degrade quickly if not reinforced with the right waterproofing materials. Ensuring the concrete structure supports both the panels and the saline environment is a top priority.

For an in-depth look at ICM’s expertise in aquatic concrete, check out their article on Aquatic Concrete Mastery: A Case Study in Structural Innovation.

Avoiding Water Leaks: The Biggest Concern for Large Aquariums

Leaks can be a nightmare in large aquariums, especially if the initial setup wasn’t performed by an experienced team. Having seen the impact of leaks on investor and client confidence, I cannot overstate the importance of choosing experienced, reliable installation teams from the start. Leaks at the concrete or acrylic level can compromise not only the structure but also the reputation of the aquarium. Correct decisions at the start are the most cost-effective investment, preventing unnecessary expenses and maintaining client trust.

Scaling the Life Support System (LSS) to the Tank Size

The Life Support System (LSS) is critical in large aquariums, as it maintains the water’s oxygen, pH, and filtration. Often, LSS providers push high-cost solutions without tailoring them to the tank’s needs. At ICM, we focus on finding the best global equipment, independently matching each unique project’s requirements without manufacturing our own systems. This approach allows us to select components that maximize efficiency without overshooting the budget.

For insights on advanced filtration systems, visit ICM’s article on Advanced Water Filtration Systems in Aquariums.

The Importance of Expert Operations and Stocking Teams

Proper species selection and themed environment design go hand-in-hand for a sustainable aquarium. My experience shows that an operations team with an in-depth understanding of fish species and environmental compatibility is essential to avoid overbudgeting due to incompatible animals or high mortality rates. The Operations & Development (O&D) department at ICM specializes in planning unique species that will thrive in the specific environment, providing a standout attraction that avoids common issues.

Designing Unique Themes for the Aquarium Ecosystem

An effective theme enhances the appeal of the aquarium while supporting the well-being of the species. ICM’s approach links environment design directly with species selection, creating habitats that look natural and support marine life. For a real-world example, see ICM’s work on the Sincere Sea Star Aquarium for insights on species selection and themed environments.

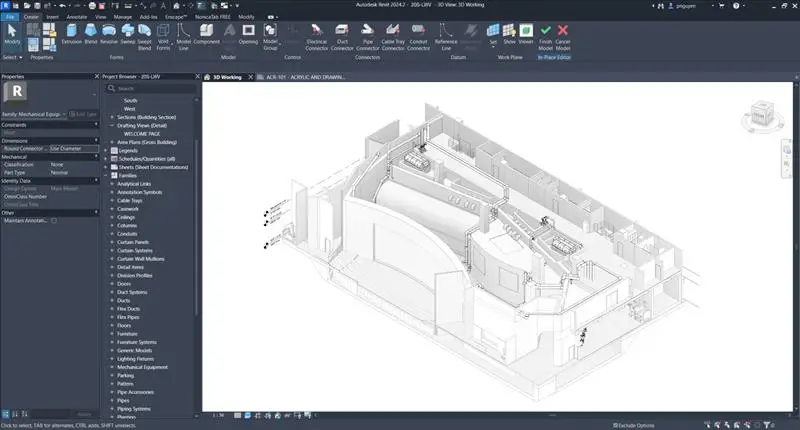

Coordinated Efforts with MEP Teams Using 3D Revit Clash Detection

The integration between Mechanical, Electrical, and Plumbing (MEP) teams and the LSS design is crucial in complex aquarium construction. I’ve seen firsthand how early-stage coordination using Autodesk Revit and Clash Detection technology can help prevent installation conflicts. This approach proved especially valuable in the Hanoi Aquarium, where our team relied on Revit’s capabilities to streamline collaboration and resolve spatial clashes in advance.

ICM’s 3D Revit Expertise Ensures Project Success

Our team’s expertise in clash detection has allowed us to proactively address installation issues before they arise, maintaining seamless operations and avoiding costly adjustments. Early detection and resolution keep projects on schedule and within budget.

Conclusion

Building a large aquarium involves addressing complex challenges that require expertise in design, installation, and maintenance. From the structural integrity of tanks to the specifics of LSS design, each decision must be made with precision and experience. At ICM, our focus on independent, tailored solutions and careful coordination with MEP teams ensures that each aquarium we design is not only beautiful but also reliable and sustainable. By investing in expertise and planning from the outset, we create large aquariums that captivate visitors while providing a safe, lasting environment for marine life.

For a comprehensive overview of the benefits of our end-to-end approach, read about ICM’s Turnkey Aquarium Projects.